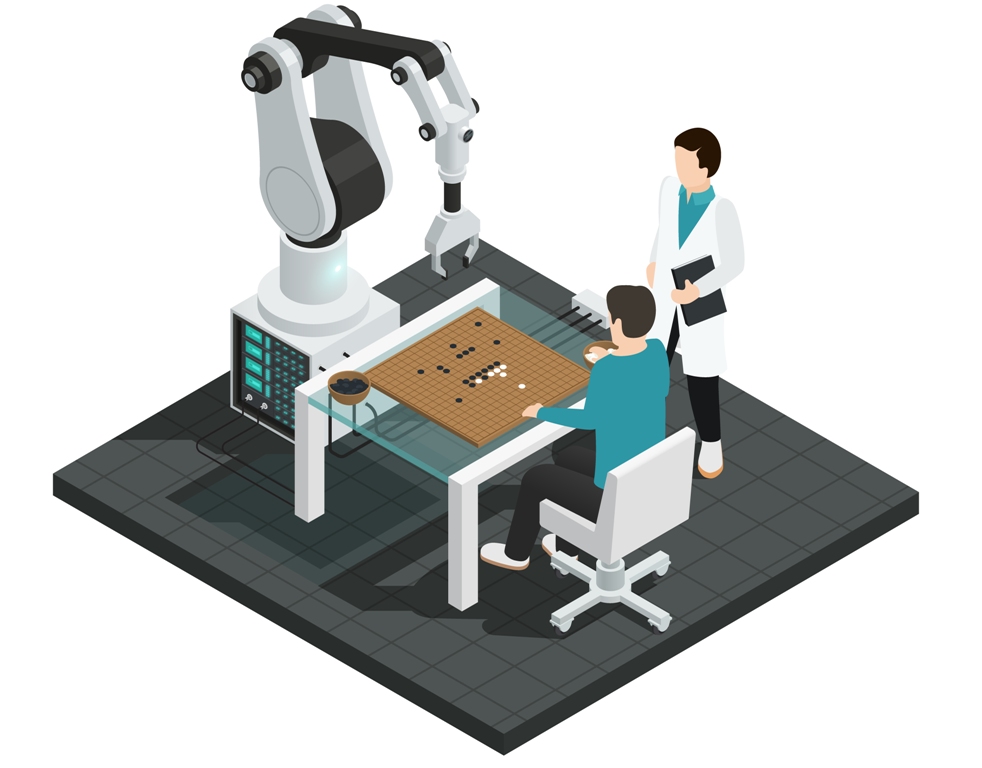

In the fast-evolving world of manufacturing, industrial robots have emerged as game-changers. These intelligent machines enhance efficiency, boost productivity, and ensure precision in production lines. From assembling products to welding, packaging, and quality control, industrial robots are transforming the manufacturing industry.

Let’s explore how these advanced technologies are shaping the future of production.

The Rise of Industrial Robots in Manufacturing

Industrial robots are no longer a futuristic concept but a necessity for modern production. With automation taking center stage, businesses are integrating robotic solutions to streamline operations and reduce dependency on manual labor.

Key industries such as automotive, electronics, food processing, and pharmaceuticals are rapidly adopting robotics to stay competitive.

Key Benefits of Industrial Robots

- Enhanced Productivity:

Robots work continuously without breaks, significantly increasing production speed and efficiency.

- Precision and Accuracy:

Advanced robotic arms and AI-powered systems ensure consistency and eliminate human errors.

- Cost Reduction:

While the initial investment is high, robots reduce long-term labor costs and minimize material wastage.

- Improved Safety:

Robots handle dangerous tasks, reducing workplace accidents and creating safer environments for human workers.

- Flexibility and Scalability:

Modern robots can be programmed to handle multiple tasks, making them ideal for dynamic manufacturing environments.

Types of Industrial Robots

- Articulated Robots: These multi-jointed robots are widely used in welding, painting, and assembly tasks.

- SCARA Robots: Best suited for pick-and-place applications due to their high-speed and precision capabilities.

- Delta Robots: Ideal for lightweight assembly and packaging operations in the food and pharmaceutical industries.

- Collaborative Robots (Cobots): Designed to work alongside humans, cobots are gaining popularity for their adaptability and ease of use.

Latest Trends in Industrial Robotics

- AI and Machine Learning Integration:

Robots are becoming smarter, learning from data to optimize processes.

- IoT and Smart Robotics:

Connected robots enable real-time monitoring and predictive maintenance.

- 3D Vision and Advanced Sensing:

Enhancing object recognition and manipulation in complex environments.

- Sustainable Manufacturing:

Robots are improving energy efficiency and reducing waste in production.

Implementing Industrial Robots: What to Consider

For businesses looking to integrate industrial robots, factors such as cost, training, maintenance, and compatibility with existing systems must be considered. Partnering with experienced automation providers can ensure a seamless transition and maximize ROI.

How Start Smart Helps Businesses?

Start Smart® empowers businesses by providing cutting-edge automation solutions, including Autonomous Mobile Robots (AMRs), to streamline operations and boost productivity. By integrating AI-driven robotics into logistics, manufacturing, and retail, Start Smart enables businesses to reduce costs, enhance efficiency, and improve workplace safety.

Whether you need to automate warehouses, optimize supply chains, or enhance real-time decision-making, Start Smart ensures seamless implementation of smart technologies tailored to your business needs.

Conclusion

Industrial robots are revolutionizing manufacturing by driving efficiency, precision, and innovation. As technology continues to evolve, the integration of robotics will become even more crucial for businesses aiming to stay ahead in the competitive landscape. Embracing automation today means securing a smarter, safer, and more productive future for manufacturing.